For some time now, globalization and technical progress have created a volatile business environment for manufacturing companies. Lately, market volatility has been further aggravated by acute crises such as Covid-19 and the war in Ukraine, all contributing to making the environment even more challenging. On many levels, this dynamic situation influences the way companies need to set up their footprint to cope with the changing demands.

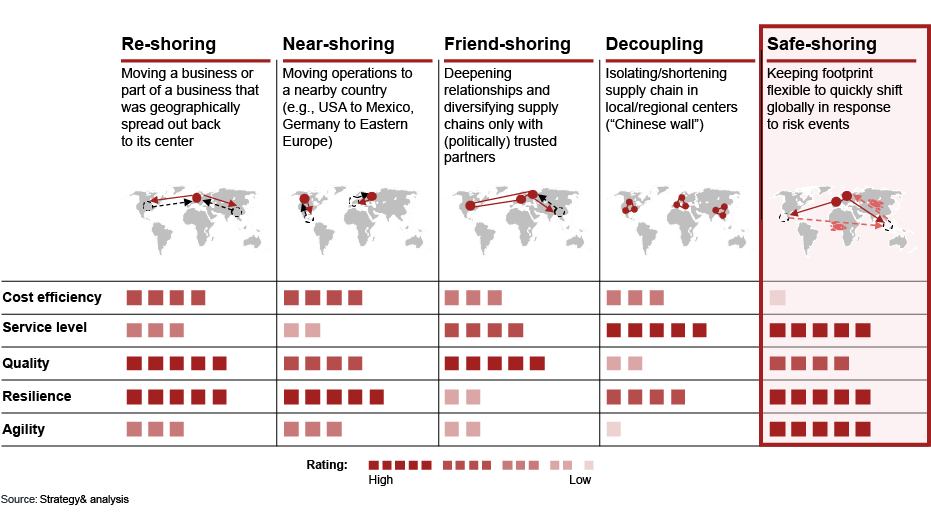

Established archetypal footprint strategies to produce “local-for-local” like Re-shoring and Near-shoring are highly resilient, as they keep the footprint close around the business center. However, this approach often leads to suboptimal market access, and excessive investments into infrastructure and know-how. In contrast, strategies like Friend-shoring and Decoupling can enable a more global footprint, but they are typically viable only in regions with low perceived risk, potentially sacrificing agility. Safe-shoring overcomes this trade-off by making agility and movability of assets a priority from the very beginning. This might result in higher initial investments but leads to lower cost when transferring the operation to another location. Lowering switching cost in the footprint allows the producer to leverage low factor cost in locations with high economic uncertainty.

Besides this, producers can achieve high levels of market proximity resulting in shorter lead times, lower working capital and personnel availability in locations that otherwise would not be chosen.

Established standards for agility and resilience enablement, already used in factory planning, should now be applied to footprint strategies

In factory planning, many principles to cope with volatility were defined in the 2010s. All these capabilities aim at making the factory's assets and resources capable of adopting to changing conditions. It is time now to also apply them on the production footprint level:

Universality

- Designing systems for versatile application

Modularity

- Developing flexible systems consisting of functional modules

Mobility

- Ensuring rapid spatial changeability with minimum effort

Scalability

- Focusing on spatial, technical and personnel adaptability

Compatibility

- Using standardized interfaces and ensuring inter- connectivity

Even though the capabilities were primarily developed for factories in the narrower sense, each capability can be interpreted in the context of Safe-shoring. The following two fictitious but practice-based use cases illustrate how approaches adopting the Safe-shoring idea – across the five capabilities – could support companies, particularly in increasing global agility and resilience.

Use case 1

A company wants to relocate its production facility to a newly-established greenfield site in another country, due to a tense political situation.

- Universality: A digital twin of the current production site exists in the form of a cloud-based building information model (BIM), serving as a blueprint for the new location to significantly accelerate the relocation process. This digital replica makes it possible to simulate material and information flows (e.g., with future suppliers) in advance. In addition, there is no risk of intellectual capital loss, since the company takes the decision to integrate and keep USP-relevant knowledge (e.g., R&D) at its headquarters

- Modularity: The production system, and therefore also the digital twin, consists of standardized functional modules (e.g., for assembly or paint shop) that can be combined using a customizable modular system. This approach allows flexible adaptations to new and local conditions to be made efficiently

- Mobility: Until the new buildings are completed, the production capacities can be set up in temporary buildings like tents as an interim solution. This is further supported by technical building equipment (e.g., water treatment plant), which remains mobile at the current facility through container solutions, ensuring easy transferability to the new site. Additionally, the foreseeable layout modifications are easy to implement using wheeled machines. In terms of personnel resources, the company has a globally-deployable team capable of handling the most important management tasks, as well as USP-creating production processes

Use case 2

Due to demand changes, a company wants to move a part of its production capacity to another existing location in a different country, to expand that location.

- Scalability: As it is particularly difficult to control volatility in takt production flows, the production model was partially transitioned to a marketplace principle in the past (e.g., for assembly). This makes it easier for the receiving site to integrate any capacity shift, simply by expanding the number of working stations. To meet new personnel requirements (e.g., for lower-skilled logistics tasks), temporary contracts are utilized to stay flexible and scalable. At the sending facility, machines have largely been leased from local service providers and can now be easily returned, under flexible contracts

- Compatibility: The introduction of a globally uniform ERP system leads to standardized interfaces and improved steering of production, simplifying the process of shifting production capacities. In addition, the use of machines that are compatible with different environments allows for increased flexibility. For example, the autonomous mobile robots used can independently create a 3D map of the new facility and generate routes accordingly. The necessary integration engineering and retooling for automation technology is further accelerated through low-code and no-code programming

These examples show how leveraging these five capabilities helps to bring Safe-shoring initiatives to life. However, implementing these initiatives also requires a high degree of operations standardization, strong management teams, and high investments.

You should evaluate if the Safe-shoring approach could be integrated into your individual footprint strategy by assessing the company’s specific situation.

Implementation of Safe-shoring can be achieved in a simplified three-step-approach:

If you are interested in finding out more about footprint strategies and Safe-shoring, please download the following PDF on future footprint considerations in the era of global crisis.

Antonia Düx and Tim Heister also contributed to this report.