CLIENT

Confidential

INDUSTRY

Automotive

SERVICE

Business model reinvention

Situation

Reinventing the business model to lead the eMobility market

The automotive industry stands at a pivotal crossroads as it evolves beyond traditional car manufacturing into an integrated mobility ecosystem. Consumers increasingly demand sustainable transportation solutions - and, in response, established OEMs find themselves navigating a complex landscape of electric vehicles, autonomous technologies, and flexible ownership models, while competing with agile BEV startups and tech giants.

This transformation extends far beyond simple product evolution. It represents a fundamental reimagining of the entire business model and mobility value chain, from manufacturing and supply networks to digital services and customer relationships.

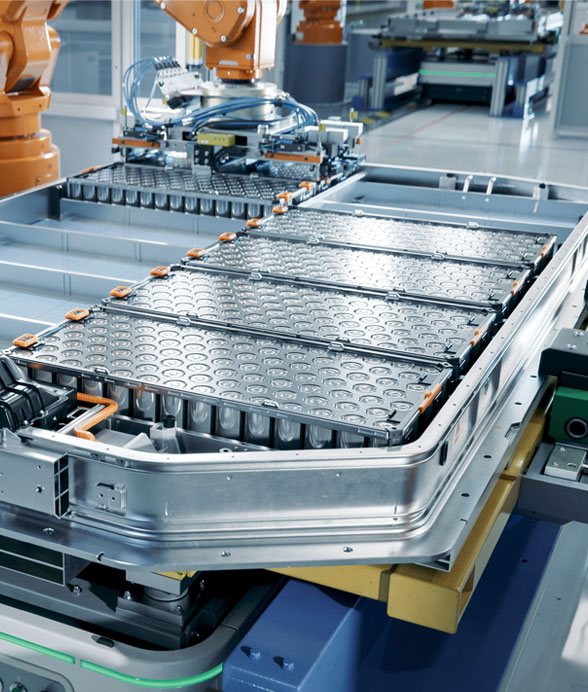

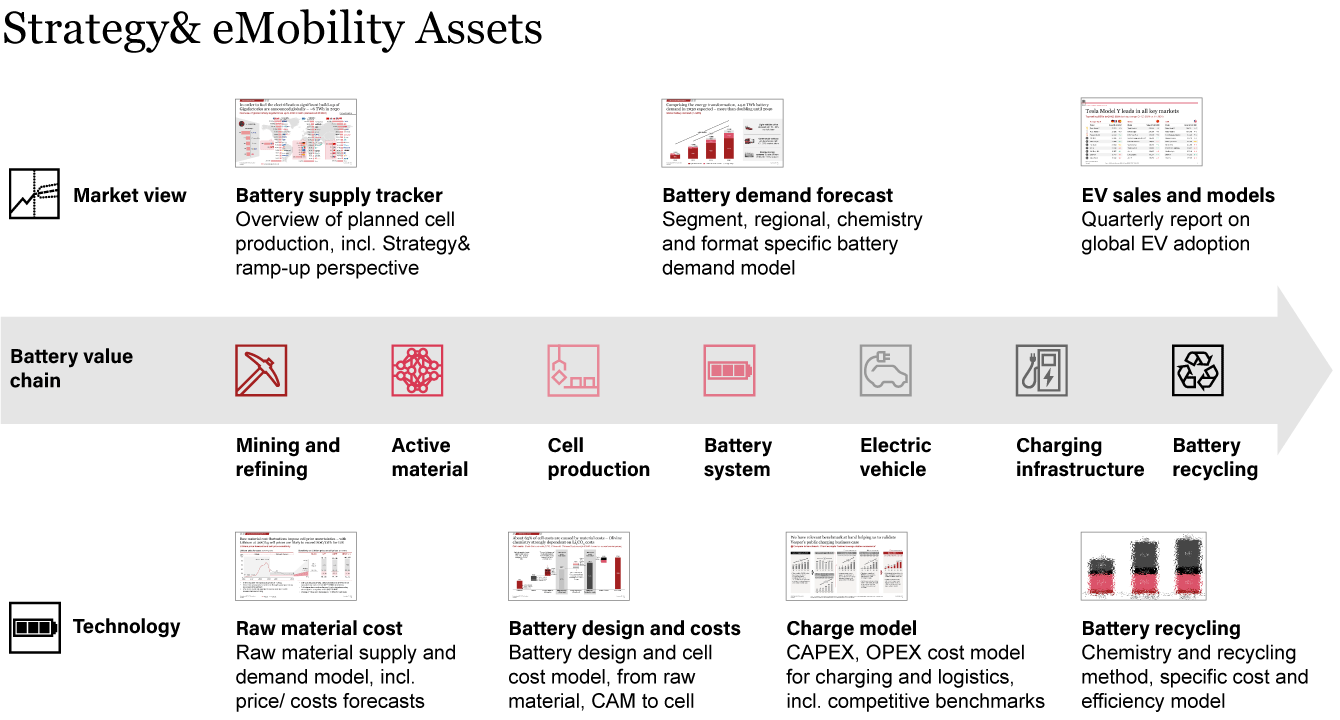

A European automotive manufacturer engaged Strategy& to strengthen its position in the eMobility market. After thorough analysis, our automotive consulting team focused on driving innovation in battery systems and cell technology - critical components to achieve competitive product performance and costs across the supply chain.

Results

Project achievements

Through this comprehensive three-phase transformation, our client evolved from a traditional manufacturer into a leading innovator in decarbonized mobility. The transformation achieved:

- Technological advancement, with the development of new capabilities in battery and cell technology

- Organizational growth, with the cultivation of essential competencies for the eMobility era; and

- Supply chain innovation, with the establishment of a resilient supply network for electric vehicle production

The success of this strategy consulting project is demonstrated by consistent market growth and significant reduction in fleet-wide CO2 emissions. The client’s eMobility offering now serves as an industry benchmark for range and cost across its entire product portfolio.

Our business model reinvention strategy in this project was built on deep market and technology insights, recognizing battery and cell technology as key differentiators in an industry where eMobility is projected to dominate from 2030 onward. Our focus areas included battery design optimization, platform strategy development, and supply chain risk mitigation - particularly focusing on lithium supply security. By forging strategic partnerships with cell technology providers and implementing robust cost management strategies, the client is now well-positioned to lead in the automotive industry's electric future.

No matter where you are on your innovation journey, whether you are just starting out or already on the road to reinvention, our sector-specific strategists work with you to evaluate and develop a future-proof business model for your success.